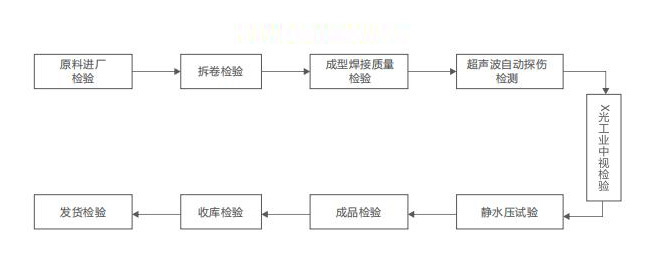

Inspection Process

Inspection Process

1. Raw material inspection:

Quality inspection and chemical inspectors conduct sampling inspection, testing and fill in inspection reports on the steel strips stored in the workshop according to the physical and chemical inspection procedures. After passing the inspection, they will issue the "Quality Approval Certificate" and the products should be supplied to the warehouse.

2. Forming welding inspection:

Forming inspectors inspect the formed steel pipes according to the inspection process regulations, mark the inspected products, fill in the inspection records, and communicate with the production personnel in time if unqualified information appears, waiting for adjustment or repair.

3. Online ultrasonic inspection:

Non-defective testing personnel conduct corresponding inspections on formed steel pipes according to the steel pipe implementation standards, mark the defects of plates and steel pipes, and fill in the inspection records.

4. Internal weld appearance inspection:

Internal weld inspectors conduct visual inspections on the internal welds of steel pipes, mark the defects accordingly, and fill in the inspection records.

5. Weld X-ray flaw detection:

Non-defective testing personnel conduct X-ray inspections on the welds of steel pipes, mark the defects, and fill in the records.

6. Repair welding inspection:

The repair welding inspector shall inspect the repair welding of the steel pipe, and the flaw detector shall inspect the repair welding according to the corresponding implementation standards and fill in the inspection record.

7. Hydrostatic pressure test:

The hydrostatic tester shall conduct a hydrostatic test on the steel pipe according to the steel pipe implementation standards and the corresponding water pressure values, mark the leaking and seepage areas, and the production personnel shall repair them.

8. Offline ultrasonic inspection:

After the hydrostatic test, the flaw detector shall conduct corresponding inspections on the formed steel pipe according to the steel pipe implementation standards at the specified time, mark the defects of the plates and steel pipes, and fill in the inspection record.

9. Finished product inspection:

The finished product quality inspector shall conduct final inspections on the products that have passed the process inspection according to the product standards and the inspection process, mark and grade the products, fill in the finished product inspection records and hand them over to the warehouse.

10. Self-inspection and sampling inspection process:

A. Self-inspection and mutual inspection

B. Operators shall conduct self-inspection and mutual inspection in accordance with the requirements of the "Product Process Technical Regulations" during the production process. If the self-inspection and mutual inspection are qualified, production will continue; if the self-inspection and mutual inspection are unqualified, the "Non-conforming Product Control Procedure" will be implemented.

C. Engineering testing and measurement

D. After each process of the product is completed, the quality inspector shall conduct random inspections according to the "Product Quality Inspection and Assessment Rules" and product standards. If qualified, it will be transferred to the next process. If unqualified, the "Non-conforming Product Control Procedure" will be implemented.

E. Completion monitoring and measurement

F. After the product is completed, the quality inspector shall inspect it item by item according to the "Product Quality Inspection and Assessment Rules".

G. After passing the inspection, the quality inspector shall stamp the product according to the provisions of the "Inspector Coding and Seal Management Measures", and fill in the "Product Inspection Record" and "Product Acceptance Form" before it can be put into storage.

H. Product performance monitoring and measurement

I. After the product is completed, if the customer requires or the company deems it necessary, the product performance should be tested and measured, and the monitoring shall be carried out according to the items and methods specified in the product standards, and the "Product Type Inspection Record", "Product Crack Resistance Test Record" and "Product Factory Inspection Record" shall be filled in.

J. Emergency/Exception Release

When a product needs to be put into use, processed or approved by the customer for delivery due to urgent production and not being tested or the test is not completed, the emergency/exceptional release application department shall fill in the "Emergency/Exception Release Application Form" and release shall be implemented after approval by the technical director. When releasing, the released product shall be marked with traceability and sample inspection shall be retained (inspection while releasing). If one of the products fails, it can be recovered in time, but appearance verification must be carried out.

If the test fails, double sampling shall be carried out. If it still fails, the pipe structure design, production equipment monitoring and debugging and test pipe production shall be re-performed, and then the test shall be carried out until it passes.

Inspection process flow chart

We sincerely invite you to join hands with XCY-PIPE

Create a brilliant future together!

Email us

For more information, please leave your message below.