Contact Info

E-mail:

WhatsApp:

Address:

No. 35 Xingye Road, Economic Development Zone, Cangzhou City, Hebei Province

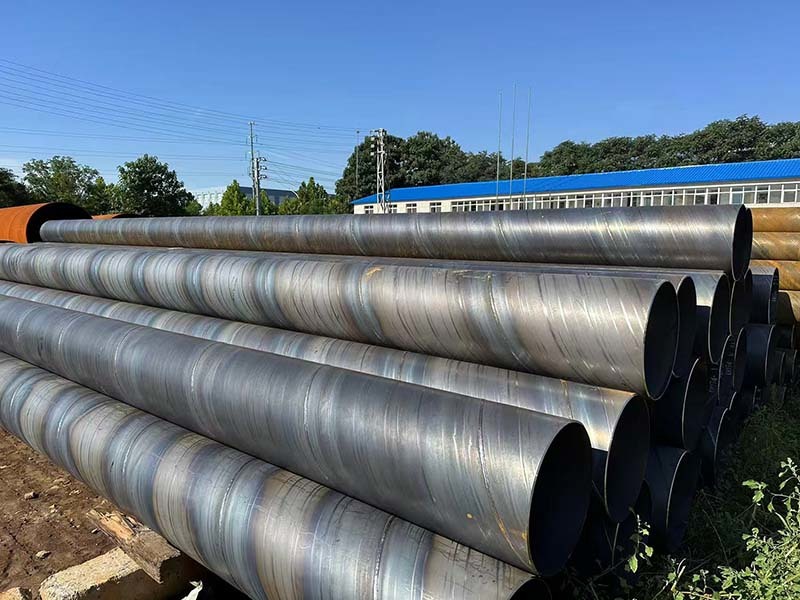

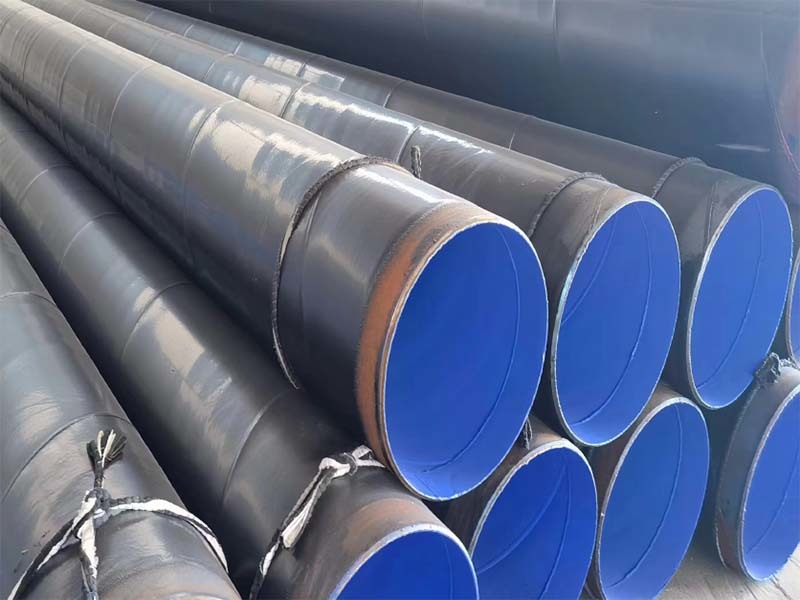

3LPE steel pipe

- Commodity name: 3LPE steel pipe

Product Introduction

3PE anti-corrosion refers to a three-layer PE anti-corrosion structure for pipelines: the first layer is epoxy powder (FBE), the second layer is adhesive (AD), and the third layer is polyethylene (PE). The color of polyethylene is generally black, but blue/yellow colors can also be produced according to different customer requirements. 2PE does not include the first layer. The three materials are integrated into one and firmly bonded with the steel pipe to form an excellent anti-corrosion layer, which can be used at a temperature of up to 70 degrees Celsius.

Common execution standards: SY/T0413-2002, GB/T23257-2009, DIN30670, etc.

The minimum layer thickness can refer to the corresponding standards.

Main quality indicators for external anti-corrosion of steel pipes

| Nominal diameter of steel pipe DN | Epoxy coating μm | Adhesive layer μm | Minimum thickness of anti-corrosion coating mm | |

| Ordinary level (G) | Enhanced Level (S) | |||

| DN≤100 | ≥120 | ≥170 | 1.8 | 2.5 |

| 100<DN≤250 | 2.0 | 2.7 | ||

| 250<DN<500 | 2.2 | 2.9 | ||

| 500≤DN<800 | ≥150 | 2.5 | 3.2 | |

| 800≤DN≤1200 | 3.0 | 3.7 | ||

| DN>1200 | 3.3 | 4.2 | ||

| Not suitable for two-layer structure rolling ethylene anti-corrosion coating. | ||||

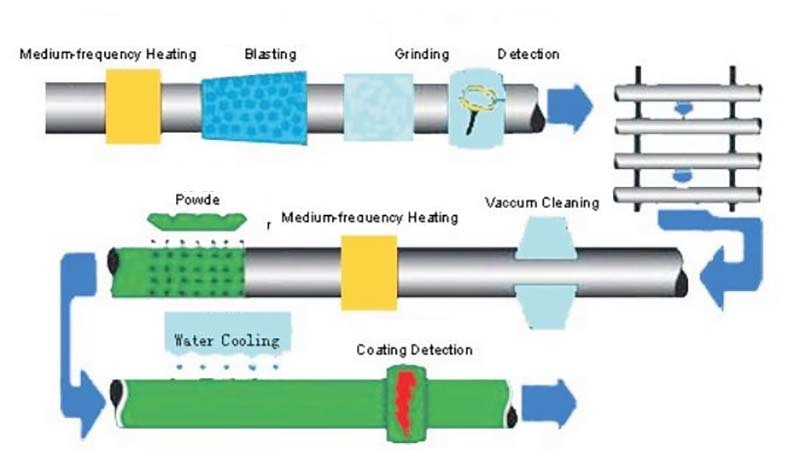

Technological process

Spiral steel pipe outer wall 3PE anti-corrosion - combined with our company's production process, the following technical measures are taken:

3PE anti-corrosion pipe production process flow:

According to the design requirements for pipeline anti-corrosion, the anti-corrosion production of steel pipes adopts an integrated mechanical assembly line production method, which can be continuously produced 24 hours a day when needed. Construction personnel are divided into three shifts and carry out handover operations. Before each process is ready and production begins, the preheating temperature and coating thickness of each layer of the anti-corrosion layer should be adjusted sequentially on the production line using a test pipe section according to the requirements of the three different anti-corrosion layers in pipeline anti-corrosion. Production can only begin after all parameters meet the requirements.

1. Appearance inspection of steel pipes

(1) Before processing, the appearance of steel pipes should be visually observed by skilled workers one by one to check for serious mechanical damage, double skin, cracks, dents, and other defects. Unqualified steel pipes cannot be used and should be marked as unqualified and returned. Only those that pass the acceptance inspection can be used for construction.

(2) If there is a flat mouth at the mouth of the steel pipe, it should be repaired by finding a circle in a timely manner. If it cannot be repaired, it should be scrapped.

2. Rust removal of pipe fittings

(1) Firstly, use a pipe gripper to transport the steel pipes that require anti-corrosion treatment to the upper pipe platform of the production line. Use a flame heater device to preheat the outer surface of the steel pipes, removing moisture, oil stains, impurities, etc. The heating temperature is controlled between 40 ℃~60 ℃ to improve the rust removal quality of the steel pipe surface.

(2) All steel pipes are derusted using the PW-380 steel pipe shot blasting machine. Before entering the shot blasting room, rubber pads or thick sponge made pipe plugs are used to block the ends of the steel pipe mouth (if the steel pipe has its own pipe plug, use its own pipe plug to block it), to prevent the steel shot from flying into the pipe mouth during the rust removal process, reduce the loss of steel shot, and ensure the amount of steel shot used during rust removal. The surface of the steel pipe after shot blasting should reach the Sa2.5 level specified in GB/T8923-1988 "Rust Grades and Preparation Grades of Steel Surfaces before Coating", and the anchor depth on the surface should be executed according to the instructions provided by the epoxy powder manufacturer.

(3) After surface pretreatment, all rust, oil stains, oxide scales, etc. should be cleaned thoroughly.

(4) Inspect the outer surface of each steel pipe one by one, and polish the surface defects that may cause coating leakage points using appropriate methods. The wall thickness after polishing should not be less than the specified value. Defective steel pipes should be removed or repaired.

(5) For steel pipes with unqualified rust removal quality, they should be promptly taken offline, the objects inside the pipes should be removed, and then returned to the production line for rust removal again.

3. Surface dust treatment of steel pipes

(1) After shot blasting and rust removal, before proceeding to the next process of epoxy powder high-voltage electrostatic spraying, the outer surface of the steel pipe is subjected to secondary treatment using a dust treatment device to remove residual rust powder and dust on the outer surface of the steel pipe. The epoxy powder coating should be applied within 4 hours. If it exceeds 4 hours or rust returns to the surface of the steel pipe, surface pretreatment must be carried out again. When treating the surface of steel pipes with fine dust, the induced draft fan on the dust removal device should be started first, and then the dust removal motor should be started; If production needs to be interrupted, the dust removal motor stop button should be pressed first, and then the induced draft fan should be stopped.

(2) Regularly clean the dust inside the cyclone vacuum cleaner to avoid excessive accumulation and affecting the dust removal effect.

(3) After starting the dust collection device, the working condition of the induced draft fan should be checked regularly.

(4) The dust removal electrode should be maintained regularly to ensure normal operation.

(5) When carrying out anti-corrosion production, the surface dust treatment of the steel pipe should be checked at least once per hour.

4. Preheating of steel pipes

(1) Before applying epoxy powder coating, the steel pipes treated with fine dust should be preheated using a KGPS-750UW constant power intermediate frequency machine. The preheating temperature must meet the requirements of the epoxy powder coating, but not exceed 275 ℃.

(2) Check the water level of the intermediate frequency circulating water tank to ensure that the water volume is at least 2.5~3 cubic meters. Start the intermediate frequency circulating water pump and check if all circulating water pipelines are leaking. Only when it is confirmed that the circulating water pipelines are in normal condition can the intermediate frequency device be started.

(3) According to the feeding speed and predetermined heating temperature of steel pipes with different diameters, adjust the output power value of intermediate frequency heating on the production line using experimental tubes.

(4) Use advanced temperature measuring instruments to measure the temperature of steel pipes during preheating, improve measurement accuracy, and ensure that the preheating temperature of steel pipes during powder coating is within the recommended range by the powder coating manufacturer.

(5) When conducting anti-corrosion production, measure and record at least once per hour to determine the preheating temperature of the steel pipe during powder coating.

5. Epoxy powder roll coating or spray coating

Epoxy powder coating is a process of applying epoxy powder coating using electrostatic spraying technology. The epoxy powder coating is sprayed onto the surface of a heated steel pipe, melted and bonded to the surface of the steel pipe, and solidified to form a coating, forming a film in one go.

6. Adhesive coating and polyethylene tape winding

(1) The coating of adhesive must be carried out during the process of epoxy powder gelatinization.

(2) When using the lateral winding process, it is necessary to ensure that the polyethylene in the overlapping part and the polyethylene on both sides of the weld are completely rolled and compacted, and to prevent damage to the surface of the polyethylene layer.

7. Circulating water cooling

After the production of the anti-corrosion coating on the steel pipe is completed, it should be cooled and fixed in a timely manner. The anti-corrosion coating surface of the steel pipe can be cooled using a circulating water pouring and coating chamber, and the cooling should be carried out in sections and stages.

(1) Before production, start the circulating water pump motor in the coating room.

(2) Adjust the valve switches of the cooling water pipes, control the size of the cooling water, and avoid the impact of excessive water flow on the anti-corrosion coating, which affects the appearance and forming quality of the coating.

(3) Before the steel pipe enters the first set of transmission wheels in the pouring and coating chamber, the first cooling water is used for cooling. In this way, the anti-corrosion coating on the surface of the steel pipe will not be damaged and will remain intact when rolled onto the first set of rubber wheels.

(4) According to the size of the pipe diameter and the difference in ambient temperature, 2-4 sections of cooling water are used for segmented cooling. The cooling temperature of the steel pipe is not higher than 60 ℃, and it is ensured that the fusion bonded epoxy coating is completely cured.

(5) The appearance of the coating should be smooth, uniform in color, free of bubbles, cracks, and shrinkage holes, with a slight orange peel pattern allowed. The coating thickness should meet the design requirements.

(6) At least the thickness of the anti-corrosion layer of the first, fifth, and tenth steel pipes should be checked for continuous production batches, and then at least one pipe should be randomly inspected for every ten pipes.

(7) If the owner has a request, it should be executed according to the owner's requirements.

8. Cutting and leaving heads

After the anti-corrosion layer of the steel pipe is cooled by cooling water, according to the requirement of reserving a length of 100-120mm at the pipe end, the end of the pipe should be ground to leave a head (1). The end face of the polyethylene layer should form a chamfer of no more than 30 degrees, and an epoxy powder coating of no more than 20mm can be retained outside the end of the polyethylene layer. The anti-corrosion layer at the end of the anti-corrosion pipe should be prevented from peeling or lifting.

(2) The end of the pipe is treated with an electric wire brush, and the operation is carried out in sections of 2-3 times to meet the standard requirements.

(3) The wire brush used for chamfering the anti-corrosion layer at the end of the grinding pipe should have a flat working surface without any protrusions or indentations.

Nspection

We pay attention to product inspection and adhere to the principle of "quality first, management first". Each product must be inspected by inspection equipment, such as industrial television testing equipment to check weld seams and appearance quality, magnetic flaw detectors to check steel pipe defects, ultrasonic automatic continuous flaw detectors to detect horizontal and vertical defects in welded steel pipes, X-ray automatic detectors and industrial television imaging equipment to check internal quality, with a sensitivity of not less than 4%. The X-ray film equipment checks the original welds and has a sensitivity of not less than 2%. Hydraulic press and microcomputer automatic recording system are used to test the pressure quality of each steel pipe. Mechanical testing equipment includes hydraulic universal testing machines and computer control systems to test welds, including tensile, guided bending, slotting machines, Charpy impact testing machines, various sample processing machines including lathes, grinding planes, grinders, and chemical composition analysis.

Production Process

(1) Process technology preparation: Select a reasonable steel strip width based on the nominal outer diameter of the steel pipe. Prepare steel pipe welding parameters, steel pipe inspection process cards, and production plans based on raw materials, and distribute them to each production and inspection process.

(2) Uncoiling process: After receiving the production process card, the qualified steel strip is lifted onto the uncoiler according to the production process requirements, and the steel strip is uncoiled and leveled.

(3) After the steel strip is leveled, it runs to the butt welding process, and the butt welding personnel perform the butt welding according to the issued welding parameters.

(4) After the welding of the steel strip is completed, it runs forward to the disc cutting process and cuts the burrs of the steel strip according to the cutting amount specified in the production process card.

(5) After cutting the edges of the steel strip, it runs to the milling process to further process the edges of the steel strip, such as removing burrs and milling off grooves on steel plates larger than 8mm.

(6) After the edge milling treatment of the steel strip, the edge of the steel strip is pre bent to form a "pout" phenomenon in the welding seam during the forming process.

(7) The steel strip enters the forming machine, and the forming worker adjusts the shape according to the issued production process card.

(8) After the steel pipe is formed, the internal welder performs internal weld welding on the steel pipe according to the issued welding parameter table.

(9) After the internal welding of the steel pipe is completed, when the weld seam rotates half a week to pass over the steel pipe, the external welder performs external welding on the weld seam.

(10) In the case of a smaller reduction rate, the steel pipe can achieve a certain required dimensional accuracy and roundness through sizing, and further improve the appearance quality of the steel pipe.

(11) After the external welding of the steel pipe is completed, it continues to move forward. When the top of the steel pipe reaches the specified length requested by the customer, it is transmitted to the plasma cutting machine through a photoelectric sensor for cutting the steel pipe to the specified length.

(12) If there are defects in the steel pipe welds, they can be manually repaired to remove the defects and proceed to the next process.

(13) Process the ends of the steel pipes to make them straight and ensure that the bevel angle meets the standard requirements.

(14) Measure the length and weight of each steel pipe, and control the weight deviation and length within the standard range.

(15) Eliminate the phenomenon of magnetic bias blowing caused by residual magnetism during steel pipe butt welding, and improve the quality of steel pipe butt welding welds.

(16) Spray labels on the inner and outer walls of one end of the steel pipe according to standards and customer requirements.

Key Words

Related Products

The company's business covers more than 60 countries including Germany, France, the United Kingdom, Singapore, Malaysia, Kazakhstan, Uzbekistan, Iran, etc.

We sincerely invite you to join hands with XCY-PIPE

Create a brilliant future together!

Email us

For more information, please leave your message below.