Contact Info

E-mail:

WhatsApp:

Address:

No. 35 Xingye Road, Economic Development Zone, Cangzhou City, Hebei Province

Elbow

- Commodity name: Elbow

Product Introduction

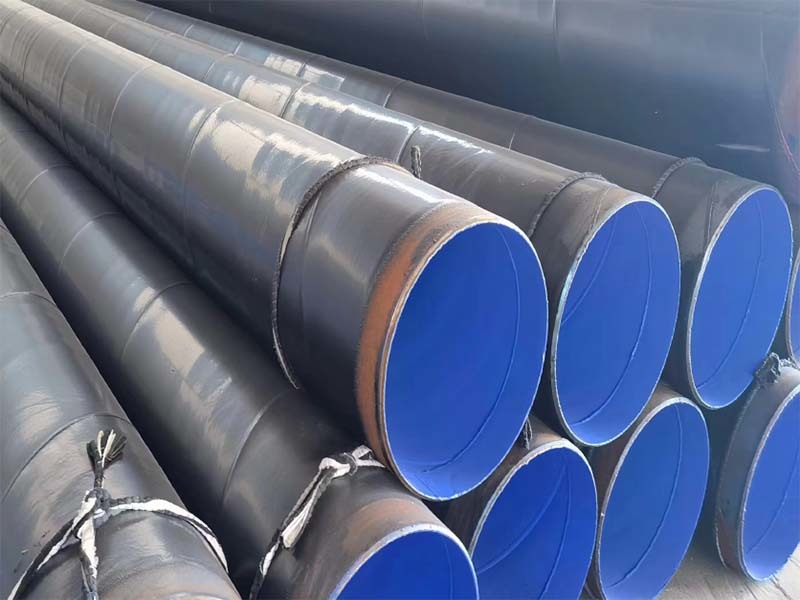

Thermal insulation elbow is one of the thermal insulation pipe fittings. It is composed of high-density polyethylene outer sleeve, polyurethane foam insulation layer and inner working steel pipe. Insulated elbows are mainly used for turning insulated straight pipes and are generally used in conjunction with insulated pipelines. They are designed to compensate for the insulation effect during pipeline design, so that the elbow part can also have sufficient insulation performance. The standard elbow angles are 30 degrees, 45 degrees, 60 degrees, and 90 degrees. Insulated elbows are widely used in liquid and gas transportation pipelines, chemical pipeline insulation engineering, petroleum, chemical, centralized heating networks, central air conditioning ventilation pipelines, and municipal engineering pipeline bends. Thermal insulation pipe (including elbows, tees, and tees) is a type of directly buried prefabricated insulation pipe with good insulation performance, safety and reliability, and low engineering cost. Effectively solves the problems of insulation pipe insulation, bending insulation, sliding lubrication, exposed pipe ends, waterproofing, and anti-corrosion at bends in various pipeline engineering such as heating, cooling, heating, power, and chemical engineering. Not only does it have advanced technology and practical performance that traditional trench and overhead pipeline laying cannot match, but it also has significant social and economic benefits, as well as energy-saving and environmental protection benefits.

Execution standards

GB/T29047-2012 High Density Polyethylene Outer Sheath Rigid Polyurethane Foam Plastic Prefabricated Directly Buried Thermal Insulation Pipe and Pipe Fittings CJ/T200-2004 Technical

Conditions for Prefabricated Directly Buried Steam Thermal Insulation Pipe for Urban Heat Supply

CJ/T104-2005 "Technical Specification for Directly Buried Steam Pipelines for Urban Heating"

SY/T114-2000. SY/T115-2001 "High density polyethylene polyurethane foam insulated steel pipe"

One type is composed of an elbow for conveying media, a corrosion-resistant outer steel pipe, and a polyurethane combination filled between the elbow and the outer steel pipe. The principle of insulation elbow is the same as that of directly buried insulation pipe, which is a new technology of waterproof, leak proof, anti-seepage, pressure resistant and fully enclosed burial. It is a major breakthrough in the use of directly buried laying technology in areas with high groundwater levels. The primary problem of the protective pipe of the directly buried pipeline is the reliability of tight waterproof. In addition, it should have good mechanical strength. Because of its high strength, the insulation elbow uses the high-density polyethylene outer pipe closely combined with the polyurethane foam insulation layer and the inner working steel pipe, so the reliability of waterproof sealing performance is very high. In addition, its high temperature resistance performance is also unmatched by other external protective pipes.

Structural mechanism

1. High density polyethylene anti-corrosion coating: High density polyethylene pipes protect elbows from corrosive substances and plant corrosion, extending the service life of pipe fittings. Support the work pipe and be able to withstand certain external loads to ensure its normal operation.

2. Polychloroester foam layer: resistant to high temperature, ensure medium temperature, ensure that the surface of the external protection pipe is kept at normal temperature, and the insulation of the internal work pipe fittings, so as to ensure that the foam is not carbonized.

3. Working steel pipe: Ensure the normal flow of the conveying medium.

Precautions for construction

1. During construction, it is necessary to avoid soaking in groundwater and rainwater. If the end is accidentally soaked in water, it should be dried before connecting the jacket.

2. The pipes should be stored on a flat surface, neatly stacked, and the stacking height should be less than 1.5 meters.

3. Pipe lifting should be carried out with care, collision and throwing are prohibited, and steel wire ropes are not allowed to directly lift the pipe body.

4. The insulation layer and anti-corrosion layer should avoid direct contact with flames.

Nspection

We pay attention to product inspection and adhere to the principle of "quality first, management first". Each product must be inspected by inspection equipment, such as industrial television testing equipment to check weld seams and appearance quality, magnetic flaw detectors to check steel pipe defects, ultrasonic automatic continuous flaw detectors to detect horizontal and vertical defects in welded steel pipes, X-ray automatic detectors and industrial television imaging equipment to check internal quality, with a sensitivity of not less than 4%. The X-ray film equipment checks the original welds and has a sensitivity of not less than 2%. Hydraulic press and microcomputer automatic recording system are used to test the pressure quality of each steel pipe. Mechanical testing equipment includes hydraulic universal testing machines and computer control systems to test welds, including tensile, guided bending, slotting machines, Charpy impact testing machines, various sample processing machines including lathes, grinding planes, grinders, and chemical composition analysis.

Production Process

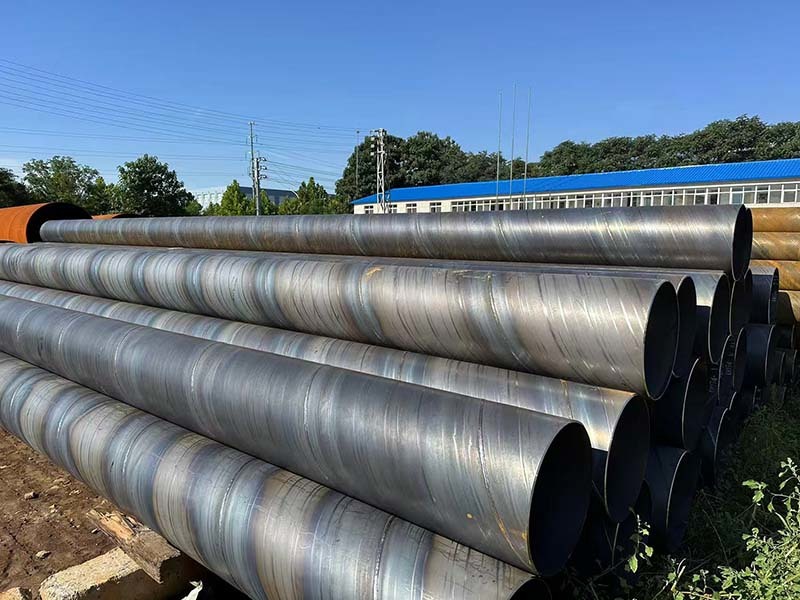

(1) Process technology preparation: Select a reasonable steel strip width based on the nominal outer diameter of the steel pipe. Prepare steel pipe welding parameters, steel pipe inspection process cards, and production plans based on raw materials, and distribute them to each production and inspection process.

(2) Uncoiling process: After receiving the production process card, the qualified steel strip is lifted onto the uncoiler according to the production process requirements, and the steel strip is uncoiled and leveled.

(3) After the steel strip is leveled, it runs to the butt welding process, and the butt welding personnel perform the butt welding according to the issued welding parameters.

(4) After the welding of the steel strip is completed, it runs forward to the disc cutting process and cuts the burrs of the steel strip according to the cutting amount specified in the production process card.

(5) After cutting the edges of the steel strip, it runs to the milling process to further process the edges of the steel strip, such as removing burrs and milling off grooves on steel plates larger than 8mm.

(6) After the edge milling treatment of the steel strip, the edge of the steel strip is pre bent to form a "pout" phenomenon in the welding seam during the forming process.

(7) The steel strip enters the forming machine, and the forming worker adjusts the shape according to the issued production process card.

(8) After the steel pipe is formed, the internal welder performs internal weld welding on the steel pipe according to the issued welding parameter table.

(9) After the internal welding of the steel pipe is completed, when the weld seam rotates half a week to pass over the steel pipe, the external welder performs external welding on the weld seam.

(10) In the case of a smaller reduction rate, the steel pipe can achieve a certain required dimensional accuracy and roundness through sizing, and further improve the appearance quality of the steel pipe.

(11) After the external welding of the steel pipe is completed, it continues to move forward. When the top of the steel pipe reaches the specified length requested by the customer, it is transmitted to the plasma cutting machine through a photoelectric sensor for cutting the steel pipe to the specified length.

(12) If there are defects in the steel pipe welds, they can be manually repaired to remove the defects and proceed to the next process.

(13) Process the ends of the steel pipes to make them straight and ensure that the bevel angle meets the standard requirements.

(14) Measure the length and weight of each steel pipe, and control the weight deviation and length within the standard range.

(15) Eliminate the phenomenon of magnetic bias blowing caused by residual magnetism during steel pipe butt welding, and improve the quality of steel pipe butt welding welds.

(16) Spray labels on the inner and outer walls of one end of the steel pipe according to standards and customer requirements.

Key Words

Related Products

The company's business covers more than 60 countries including Germany, France, the United Kingdom, Singapore, Malaysia, Kazakhstan, Uzbekistan, Iran, etc.

We sincerely invite you to join hands with XCY-PIPE

Create a brilliant future together!

Email us

For more information, please leave your message below.